Since the advent of weather applications for radar following the Second World War, engineers and operators have historically encountered several significant challenges. From data processing accuracy to radar investments' maintenance and longevity, the need has been clear for improved clutter suppression, automated calibration, maintenance, and remote monitoring. The points are especially critical when one or more radars are used as a primary data point for an integrated meteorological network.

The key objective when developing the Baron Gen3 series of weather radar was solving these challenges. In doing so, Baron engineers implemented new techniques and technologies to ensure precision hydrometeorological detection with maximum possible uptime and reduced manpower.

Automated Calibration

A properly calibrated radar is essential to the success of meteorological organizations. An uncalibrated or poorly calibrated radar generates degraded base data, limiting its usefulness and contributing to erroneous weather forecasts. When major storms are tracked across a network of radars, the combination of data required from several radars makes it crucial that the entire network is calibrated to a commonly known standard. In addition, since base data is used to generate products for rainfall estimation, hail detection, and rain/snow discrimination, significant errors in the derived products can be caused by small mistakes in the base data.

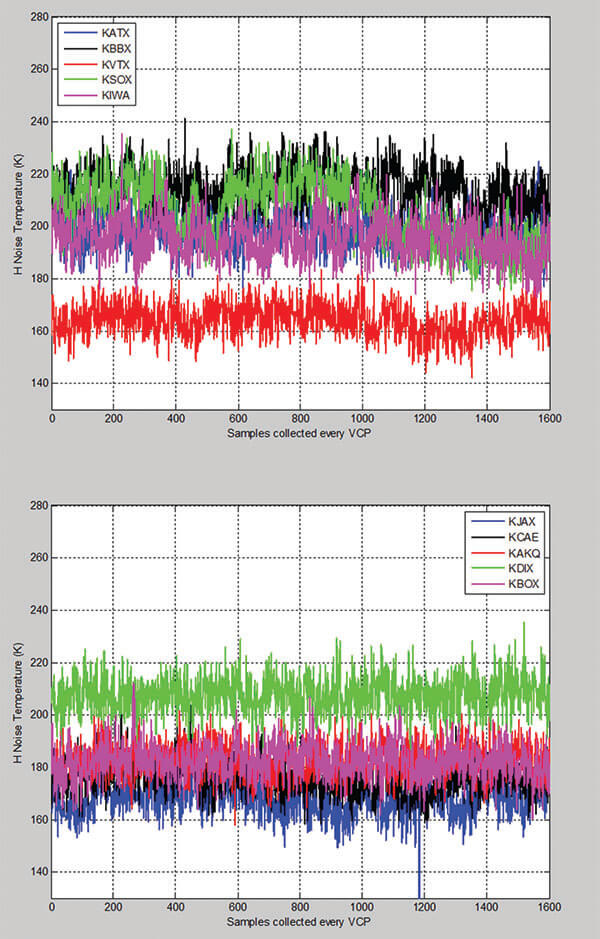

A team of Baron radar meteorologists and engineers had previously developed an innovative calibration routine for the nationwide dual-polarization upgrade to NEXRAD for the U.S. National Weather Service, Federal Aviation Administration, and Department of Defense, conducting a calibration routine during the approximately six-second period of antenna retrace following a completed volume scan. For the Gen3 series, that routine was adapted and enhanced to provide continuous automated bin-by-bin ZDR calibration

Previously, radar systems could only be calibrated once or twice a year. On-site personnel needed to wait for clear, rain-free days when they could halt weather surveillance and reorient the antenna to the azimuth angle.

ZDR, often called Differential Reflectivity, is the basis for these calibrations. ZDR was chosen due to its importance for calculating Hydrometeor Classification. Once foundational dual-pol moments were calibrated to .1dB accuracy; it was found that all other data products would follow, benefitting from the improvements.

Next-generation calibration technology solves several operational challenges: first, no human interaction is involved, calibration errors are avoided, and reliable network-wide calibration is enabled. Calibration can be performed in any weather; the new technique accounts for rain and other detrimental effects (e.g., seams, bird droppings, and natural wear) on the radome and requires no solar measurements. Additionally, no hardware measurements are needed, reducing equipment needs and the opportunity for error.

Clutter Suppression

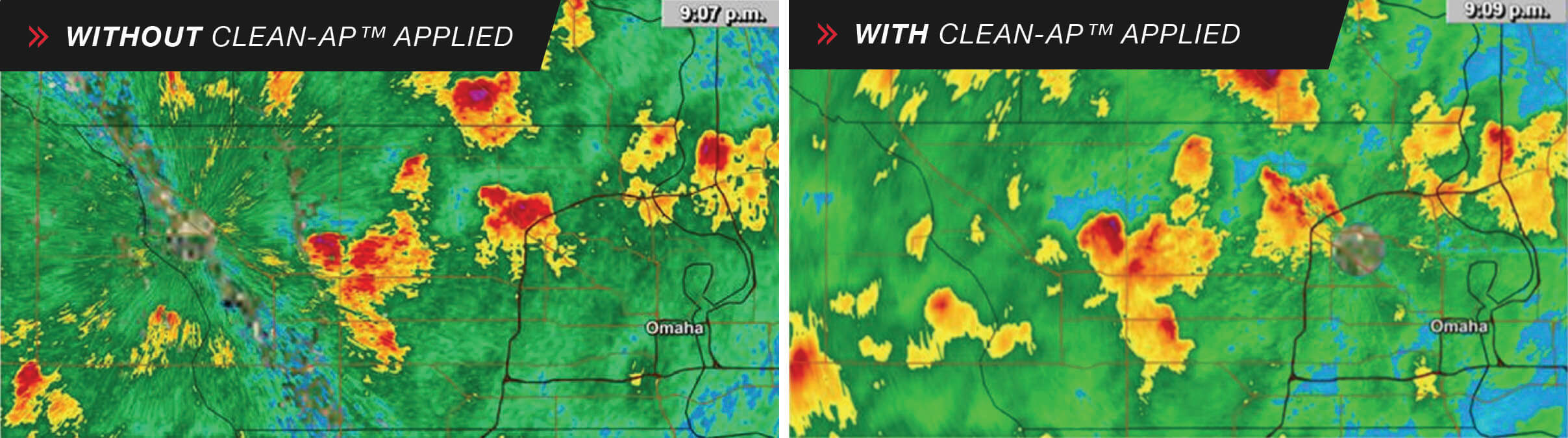

Clutter caused by terrain, moisture, buildings—even bird and insect migrations—can wreak havoc on an accurate radar display and, in turn, value-added products generated by the radar. In the late 2000s, the University of Oklahoma’s Cooperative Institute for Mesoscale Meteorological Studies (CIMMS) developed the initial implementation of the CLEAN-AP™ (Clutter Environment ANalysis using Adaptive Processing) clutter filtering technique. Baron partnered with OU, licensing CLEAN-AP™ for exclusive use in its radar systems.

The advantages of CLEAN-AP compared to older ground clutter filters include:

- CLEAN-AP™ performs automated clutter detection and suppression without manual intervention.

- The need for clutter maps is eliminated through CLEAN-AP™’s real-time ground clutter detection capability.

- CLEAN-AP™ uses adaptive data windowing that accomplishes a good compromise between clutter suppression and data quality.

- CLEAN-AP™ is an integrated process providing a single algorithm for ground clutter detection and filtering on a bin-by-bin basis.

The unique clutter-filtering ability of CLEAN-AP™ is vital when being used as part of an integrated network. By significantly improving the accuracy of base data, benefits occur throughout the system, from data collection and integration to forecast models, ultimately leading to more effective forecasts and alerts for the general public.

Remote Monitoring and Maintenance

Every meteorological organization deals with the continuing balance of technical demands weighed against a relative lack of personnel and financial resources. The Gen3 radar series’ Built-In Test Equipment (BITE) continuously monitors system status. Evaluated parameters include temperature of vital systems, power supply voltages and currents, waveguide switch positions, transmitter performance, calibration status, and more.

If the diagnostics detect faults, operators are automatically notified via email, and the system monitors the interface. This capability allows any issues to be corrected before the system fails. Additionally, system components are more easily replaced because of the modular system architecture inherent to Baron Gen3 radar. The result is that users experience more productive uptime, with less personnel and better accuracy, throughout their meteorological detection network.

The modular design allowed users to upgrade or replace components as needed quickly. Maximum commonality between systems means that users can keep spare parts in stock across the whole network, enabling faster component replacement and lower costs.

Unparalleled Support

Baron Gen3 systems are now active worldwide in fixed, transportable, and mobile designs. C-band, X-band, S-band, and High-frequency S-band configurations are available. This highlights the need for outstanding support. Baron operates a worldwide support center manned 24/7/365 by degreed meteorologists knowledgeable about radar and weather, globally providing Baron customers with unparalleled support. This same team can monitor the BITE diagnostics 24/7/365, providing a supporting role as a complete Radar Operations Center (ROC), providing customers with peace of mind and maximum return on investment in the field.

One of the initial Gen3 installations, performed for a commercial entity in the United States, resulted in the high-frequency S-band system successfully detecting the outer fringes of Hurricane Matthew. At the same time, the storm was well offshore, obtaining extremely accurate, high-resolution measurements once the storm approached the radar site. This was accomplished within hours of the radar’s installation, with its scheduled completion accelerated as the storm’s path was predicted to make landfall.